Working Principle

The fume comes from the processing will be sucked into the extractor through the hood, first the fume passes the 1st layer preventer plate which will ramify the fume to avoid residual sparks enter into filter layer directly. Finally, the fume enters the second layer of HEPA filter cartridge for ultimate purification, and HEPA 's filtration efficiency can reach 99.9%. As the filtering precision of the main filter cartridge reaches the indoor emission standard, the filtered clean air can be directly discharged indoor via the vent in the bottom of the extractor.

Product introduction

Mobile welding fume extractor are designed to be utilized as a respiratory safety engineering control during a variety of welding applications, including TIG welding, MIG welding, maintenance welding, production welding, clean room welding, stick welding, stainless steel tank welding, rapid location welding, and much more. It has two directional and two rotary polyurethane casters with brake device for easy moving and stationing.

Main feature

1. Low amounts of smoke/dust

2. Occasional use

3. Depending on needs, 2m, 3m flexible suction arm are available.

4. Semi-automatic/manual cleaning

5. CE certification, EMC certification

6. Operating controls conveniently

Standard Parameters

| No. | Item | Parameter |

| 1 | Fan type | centrifugal fan |

| 2 | Treatment of air flow | 1000±100 m3/h |

| 3 | Motor power | 0.75kW |

| 4 | Power supply | 220-240V ~/50Hz |

| 5 | Filtration area | 20 m2 |

| 6 | Number of filter cartridges | 1 piece |

| 7 | Filter medium | Synthetic wood pulp fiber filter paper |

| 8 | Filtration efficiency | >99.9% |

| 9 | Noise | ≤74±5dB(A) |

| 10 | Ash hopper volume | 2 L |

| 11 | One suction arm | Ø160mm*2m |

| 12 | Weight (excluding suction arm) | 98±5KG |

| 13 | Dimensions(excluding suction arm) | 510×610×990mm |

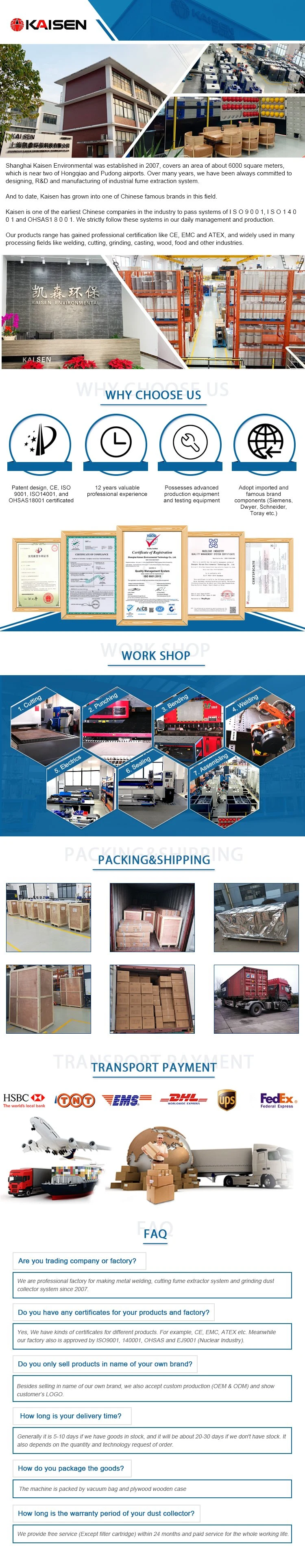

Company profile